Ferroloy, Inc. provides ductile iron castings to manufactures throughout the USA. We are a turnkey supplier of cast ductile iron parts for the agriculture, construction, industrial equipment, hydraulics and valves industries. Our ductile iron foundry is centrally located in Wichita, KS.

Whether you have a design ready for casting, or you need a custom casting design, we can help. Ferroloy has the capabilities to produce cast iron parts for your needs from start to finish. We produce ductile iron castings up to 50lbs.

Contact us today at 316-838-0897 to learn more about ductile iron castings or request a quote online.

What Is Ductile Iron?

Ductile iron is a kind of cast iron characterized by its high strength, ductility and wear resistance. Due to the spherical (ball-shaped) graphite in the metal, it is resistant to impact, elongation and everyday wear and tear.

Advantages of Ductile Iron Castings

Ductile iron castings combine the processing advantages of a low melting point, good fluidity and machinability. It also has many of the engineering advances of steel including high strength, ductility and wear resistance. These qualities allow for a much higher tensile and yield strength as well as a lower damping capacity.

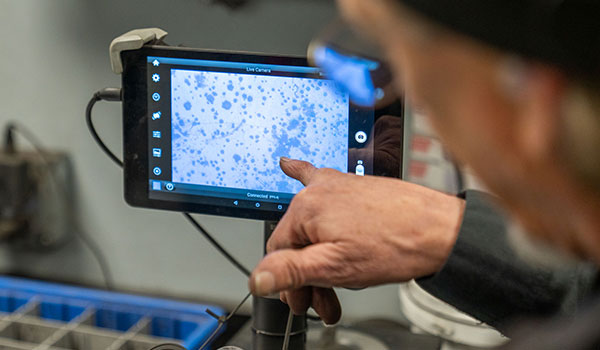

Ductile Iron Castings Microstructure

Ductile iron, also referred to as nodular cast iron or spheroidal graphite iron, has an unusual combination of properties obtained because the graphite occurs as spheroids rather than flakes as in gray iron. This mode of solidification is obtained by adding a very small but specific amount of magnesium to molten iron. The allowable content of minor elements that can interfere with the graphite spheroid formation in the base iron is severely restricted. The added magnesium reacts with the sulfur and oxygen in the molten iron and changes the way the graphite is formed.

Tensile & Yield Strength

Ductile iron has a minimum tensile strength of 60,000 psi and a minimum yield strength of 40,000 psi. Ductile iron’s commonly established properties are tensile strength, yield strength and percent elongation. Because of the nominal and consistent influence of spheroidal graphite, the tensile properties and the Brinell hardness of ductile iron are well correlated.

Low Damping Capacity

The relative ability of a material to absorb vibration is evaluated as its damping capacity. The quelling of vibration by converting the mechanical energy into heat can be important in structures and devices with moving parts. Ductile iron has a relative damping capacity of 0.14, significantly less than that of a similar gray iron part with a damping capacity of 1. Still, ductile iron compares favorably versus steel alloys in terms of damping capacity.

Best Use For Ductile Iron Castings

Due to their increased strength and ductility, these types of castings are best used for:

- Value Bodies

- Compressor Valves

- Couplings

- Sprocket Wheels

- Hydraulic Valves & Cylinders

- Structural Brackets

- Rollers

- Cable Drums

- Frames

- Pumps

- Crankshafts

- Camshafts

- Exhaust Manifolds

- Machine frames

- Flanges

- Hubs

- Gear Boxes

Ductile Iron Casting Foundry

Looking for a partner to assist with ductile iron part casting? Our team of experts work with design engineers to adequately determine the best method for part production.

OEMs can typically reduce costs up to 60% by converting to a casting. Contact Ferroloy today and let us show you how.

The ductile iron casting at Ferroloy is throughly examined by our quality assurance team.

Contact our iron foundry today to discuss a turnkey solution for you.

Request Information